Call us: (403) 394-2406

News

- HOME

- NEWS

February 6, 2026 - ISSUE 27

The WAGS Word

THE WAGS TEAM

Happy New Year!

What a great start to the year. January kicked off with the Banff Pork Seminar, further investment in Canada into egg grading, and continued optimism in the livestock production world. In short, livestock supply numbers in North America have been down, prices have been up, and demand has been strong!

Banff was a great time once again this year seeing customers, partners and suppliers, and hearing some wonderful educational talks. Some highlights were plenary session global pork economics presentations and great break out sessions including one top of mind to us all - sow barn renovations. On the economic side, the projection was strong margins available to be covered for hog producers through 2026!

On the laying hen side, we continue to see strong markets and recent expansionary investments in egg grading facilities with the most recent announcement in Listowel, Ontario. Once again, optimism in many sectors of the livestock industry.

WAGS major personnel announcement for last quarter is that Darcy MacDonald has moved into the position of Director of Business Development. Darcy has been an integral part of growing the Western Ag Supply business in Saskatchewan. In his new role, he will continue to support the Saskatchewan business and will also work to support the WAGS teams in Alberta and Montana to continue to help our team serve and grow with our customers in those areas. Darcy is looking forward to further supporting WAGS customer partners succeed across these regions!

We thank you for your partnership over the past year and are looking forward to a prosperous 2026 for livestock producers!

What a great start to the year. January kicked off with the Banff Pork Seminar, further investment in Canada into egg grading, and continued optimism in the livestock production world. In short, livestock supply numbers in North America have been down, prices have been up, and demand has been strong!

Banff was a great time once again this year seeing customers, partners and suppliers, and hearing some wonderful educational talks. Some highlights were plenary session global pork economics presentations and great break out sessions including one top of mind to us all - sow barn renovations. On the economic side, the projection was strong margins available to be covered for hog producers through 2026!

On the laying hen side, we continue to see strong markets and recent expansionary investments in egg grading facilities with the most recent announcement in Listowel, Ontario. Once again, optimism in many sectors of the livestock industry.

WAGS major personnel announcement for last quarter is that Darcy MacDonald has moved into the position of Director of Business Development. Darcy has been an integral part of growing the Western Ag Supply business in Saskatchewan. In his new role, he will continue to support the Saskatchewan business and will also work to support the WAGS teams in Alberta and Montana to continue to help our team serve and grow with our customers in those areas. Darcy is looking forward to further supporting WAGS customer partners succeed across these regions!

We thank you for your partnership over the past year and are looking forward to a prosperous 2026 for livestock producers!

Commodity Price Update

TOM and DARCY

tomd@westernagsupply.com ; darcy@westernagsupply.com

As we enter 2026, geopolitics continues to dominate the headlines. An inflection point was the World Economic Forum in Davos where Canada’s Prime Minister gave a speech that caught the attention of the world as Carney proclaimed a changing world order.

While changes will no doubt lead to some ebbs and flows of global trade routes, there appears to be ample supply of grain and oilseeds which may keep input prices in check over the next year. This bodes well for livestock producers given the relatively low stocks of cattle driving prices of animal proteins up.

In western Canada, a good harvest has provided good stocks of wheat and barley. Combined with the price ceiling provided by corn coming from Manitoba and US, these factors have led to prices trading sideways since harvest. Wheat has been at $285-290 delivered Lethbridge and around $280 Saskatoon area. Barley has been trading at $265-270 delivered Lethbridge and $255-260 delivered Saskatoon.

While projections are not calling for major price increases, geopolitical, weather and currency uncertainty always has the potential to lead to unexpected price movements. While proteins saw a November spike in soybean meal prices with China-US trade announcements, sufficient supply and strengthening CAD has brought prices from highs of around $600 all the way back down to $520-530 delivered of late in Southern Alberta and $480-490 Swift Current and Saskatoon. It should be noted that China has filled the negotiated US volume and has recently gone back to buying South American soybeans. This reduces the risk of an export driven price increase.

On the Canadian supply side, the major story over the past few weeks has been the trade deal struck between Canada and China. This led to reduction of tariffs on canola products and the price of canola meal spiking by around $60. Prices have settled to around $360-370 delivered regions of southern and central Alberta, and prices of $335-345 across parts of Saskatchewan. Pulses have increased by $20-30 per MT with expectations that Chinese tariffs may be reduced. However, there has not been clear confirmation of tariff changes on pulses as of the time of writing this article.

Current outlooks show relatively flat input prices through most of 2026 which should be supportive of strong margins from livestock production.

While changes will no doubt lead to some ebbs and flows of global trade routes, there appears to be ample supply of grain and oilseeds which may keep input prices in check over the next year. This bodes well for livestock producers given the relatively low stocks of cattle driving prices of animal proteins up.

In western Canada, a good harvest has provided good stocks of wheat and barley. Combined with the price ceiling provided by corn coming from Manitoba and US, these factors have led to prices trading sideways since harvest. Wheat has been at $285-290 delivered Lethbridge and around $280 Saskatoon area. Barley has been trading at $265-270 delivered Lethbridge and $255-260 delivered Saskatoon.

While projections are not calling for major price increases, geopolitical, weather and currency uncertainty always has the potential to lead to unexpected price movements. While proteins saw a November spike in soybean meal prices with China-US trade announcements, sufficient supply and strengthening CAD has brought prices from highs of around $600 all the way back down to $520-530 delivered of late in Southern Alberta and $480-490 Swift Current and Saskatoon. It should be noted that China has filled the negotiated US volume and has recently gone back to buying South American soybeans. This reduces the risk of an export driven price increase.

On the Canadian supply side, the major story over the past few weeks has been the trade deal struck between Canada and China. This led to reduction of tariffs on canola products and the price of canola meal spiking by around $60. Prices have settled to around $360-370 delivered regions of southern and central Alberta, and prices of $335-345 across parts of Saskatchewan. Pulses have increased by $20-30 per MT with expectations that Chinese tariffs may be reduced. However, there has not been clear confirmation of tariff changes on pulses as of the time of writing this article.

Current outlooks show relatively flat input prices through most of 2026 which should be supportive of strong margins from livestock production.

PIG TALK

Why Analyzing Feed Ingredients Pays Off in Pig Production

Mario

marior@westernagsupply.com

Feed represents 60–70% of the total cost of producing a pig. Because margins are tight, small improvements in feed efficiency and ingredient use can make a big difference to the bottom line. One of the most effective — and often underused — tools to improve profitability is proper analysis of feed ingredients before formulation.

Feed ingredients are not all the same

Many pig diets are formulated using book values for energy, protein, amino acids, fiber, and minerals. While these averages are useful, they do not reflect the true variability in ingredients such as corn, wheat, barley, soybean meal, DDGS, or canola meal.

Moisture content, growing conditions, processing method, and storage all affect nutrient levels. Two loads of the “same” ingredient can differ significantly in energy or digestible amino acids. Without analysis, diets may be over- or under-formulated, both of which cost money.

Avoid over-formulation and unnecessary cost

When nutritionists assume nutrients are lower than they really are, they compensate by adding more expensive ingredients or supplements. This “safety margin” increases feed cost with no added performance benefit.

For example:

- Overestimating protein variability can lead to excess soybean meal

- Underestimating energy can increase fat or oil inclusion

- Inaccurate phosphorus values increase mineral and phytase costs

Proper ingredient analysis allows diets to be formulated closer to the pig’s actual requirement, reducing unnecessary ingredient expense while maintaining performance.

Prevent under-formulation and performance losses

Under-formulated diets are even more costly. If pigs receive less energy or digestible amino acids than expected:

- Growth rate slows

- Feed conversion worsens

- Days to market increase

- Carcass weight and lean yield may decline

Even small drops in feed efficiency or average daily gain can erase profits quickly, especially in finishing pigs. Regular ingredient analysis helps ensure pigs receive what the formulation intends, every day.

Improve use of enzymes and alternative ingredients

Ingredient analysis is especially important when using:

- Enzymes (phytase, xylanase, beta-glucanase, etc.)

- Alternative or by-product ingredients

- High-fiber diets

Knowing the actual fiber, starch, and phosphorus levels allows enzymes to be applied accurately and economically. This improves nutrient release and reduces over-supplementation, maximizing return on investment from enzyme use.

Reduce risk and increase consistency

Feed consistency is key to predictable pig performance. Ingredient testing reduces the risk of:

- unexpected nutrient shortfalls

- excess manure nutrients

- variability between batches of feed

A 1% mistake in crude protein content in animal diets can cost producers between $7.00 and $8.00 at current prairie feed prices, and additional errors in energy or phosphorus levels can push costs even higher.

More consistent feed means more consistent pigs, which simplifies management and improves marketing outcomes.

A small cost with a big return

The cost of ingredient analysis is small compared to the value of:

- Improved feed efficiency

- Faster growth

- Lower feed cost per tonne

- Reduced nutrient waste

In most cases, accurate ingredient data pays for itself many times over.

Bottom line

Proper feed ingredient analysis is not just a nutrition tool — it is a profit management strategy. By knowing what is truly in your feed ingredients, you can formulate more precisely, reduce feed costs, protect pig performance, and improve overall farm profitability.

In today’s high-cost production environment, guessing is expensive — measuring pays.

Feed ingredients are not all the same

Many pig diets are formulated using book values for energy, protein, amino acids, fiber, and minerals. While these averages are useful, they do not reflect the true variability in ingredients such as corn, wheat, barley, soybean meal, DDGS, or canola meal.

Moisture content, growing conditions, processing method, and storage all affect nutrient levels. Two loads of the “same” ingredient can differ significantly in energy or digestible amino acids. Without analysis, diets may be over- or under-formulated, both of which cost money.

Avoid over-formulation and unnecessary cost

When nutritionists assume nutrients are lower than they really are, they compensate by adding more expensive ingredients or supplements. This “safety margin” increases feed cost with no added performance benefit.

For example:

- Overestimating protein variability can lead to excess soybean meal

- Underestimating energy can increase fat or oil inclusion

- Inaccurate phosphorus values increase mineral and phytase costs

Proper ingredient analysis allows diets to be formulated closer to the pig’s actual requirement, reducing unnecessary ingredient expense while maintaining performance.

Prevent under-formulation and performance losses

Under-formulated diets are even more costly. If pigs receive less energy or digestible amino acids than expected:

- Growth rate slows

- Feed conversion worsens

- Days to market increase

- Carcass weight and lean yield may decline

Even small drops in feed efficiency or average daily gain can erase profits quickly, especially in finishing pigs. Regular ingredient analysis helps ensure pigs receive what the formulation intends, every day.

Improve use of enzymes and alternative ingredients

Ingredient analysis is especially important when using:

- Enzymes (phytase, xylanase, beta-glucanase, etc.)

- Alternative or by-product ingredients

- High-fiber diets

Knowing the actual fiber, starch, and phosphorus levels allows enzymes to be applied accurately and economically. This improves nutrient release and reduces over-supplementation, maximizing return on investment from enzyme use.

Reduce risk and increase consistency

Feed consistency is key to predictable pig performance. Ingredient testing reduces the risk of:

- unexpected nutrient shortfalls

- excess manure nutrients

- variability between batches of feed

A 1% mistake in crude protein content in animal diets can cost producers between $7.00 and $8.00 at current prairie feed prices, and additional errors in energy or phosphorus levels can push costs even higher.

More consistent feed means more consistent pigs, which simplifies management and improves marketing outcomes.

A small cost with a big return

The cost of ingredient analysis is small compared to the value of:

- Improved feed efficiency

- Faster growth

- Lower feed cost per tonne

- Reduced nutrient waste

In most cases, accurate ingredient data pays for itself many times over.

Bottom line

Proper feed ingredient analysis is not just a nutrition tool — it is a profit management strategy. By knowing what is truly in your feed ingredients, you can formulate more precisely, reduce feed costs, protect pig performance, and improve overall farm profitability.

In today’s high-cost production environment, guessing is expensive — measuring pays.

IT’S CHICKEN FEED

From Feed to Yolk: Fat Metabolism in Laying Hens and Its Role in Omega-3 Enriched Egg Production

SANTOSH and RUBEN

santosh@westernagsupply.com; rubeng@westernagsupply.com

Eggs are considered one of nature’s most perfect foods. Today, consumers are increasingly seeking out functional foods that offer specific health benefits. Omega-3 enriched eggs represent a valuable functional food that can address dietary deficiencies in essential fatty acids while providing economic opportunities for poultry producers. According to Egg Farmers of Canada, specialty eggs (including omega-3, vitamin-enhanced, and organic) now represent approximately 18-20% of total egg sales by value, with omega-3 enriched eggs being a dominant segment (EFC, 2023). Conventional eggs naturally contain modest amounts of omega-3s, typically around 25-50 mg per egg, primarily as alpha-linolenic acid (ALA) and docosahexaenoic acid (DHA). Through omega-3 enrichment programs used by producers across Western Canada, total omega-3 content can increase significantly. Under current nutritional claim standards, a 53-gram omega-3 enriched white egg contains 400 mg of total omega-3 fatty acids, including 75 mg of docosahexaenoic acid (DHA), while also providing approximately 800 mg of total omega-6 fatty acids. In Montana, omega-3 enriched eggs marketed through grader stations such as Wilcox Family Farms typically contain approximately 200–250 mg of total omega-3 fatty acids per egg, including around 60 mg of DHA, with the remaining omega-3 content primarily as ALA.

What are omega fatty acids? Omega fatty acids are polyunsaturated fatty acids (PUFAs) that play essential roles in human health. The most important ones in egg enrichment programs are:

- ALA (α-linolenic acid) – plant-based (flaxseed, canola)

- EPA (eicosapentaenoic acid) – marine origin

- DHA (docosahexaenoic acid) – marine origin, most biologically valuable

Omega-3 fatty acids and human health

Omega-3 PUFAs play critical roles in physiological processes. DHA and EPA, long-chain omega-3s, are associated with cardiovascular health, anti-inflammatory effects, and neural development. A clinical study demonstrated that consumption of omega-3-enriched eggs increased plasma DHA levels significantly compared with regular eggs over 30 days, showing potential to improve systemic omega-3 status in humans (Benny et al., 2025). The enrichment of eggs with omega-3 PUFAs may also improve lipid health indices, such as favorable atherogenic and thrombogenic indexes, suggesting a potential role in chronic disease risk reduction (Radanović et al., 2023).

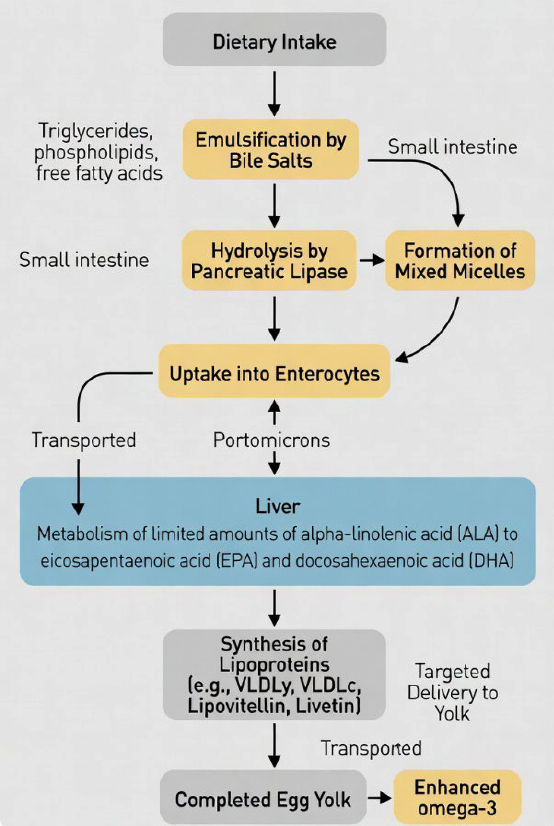

Fat metabolism and nutritional basis for enrichment in layers

In laying hens, the efficient transfer of dietary fats into the yolk is a direct, hepatic-driven process. Fats from the diet are digested in the small intestine. Bile salts emulsify fats into small droplets, and pancreatic enzymes hydrolyze them into absorbable fatty acids. These are taken up by intestinal cells and packaged into portomicrons—a lipoprotein unique to birds. Due to their less developed lymphatic system compared to mammals, these portomicrons are transported directly to the liver via the portal blood. This direct hepatic portal route allows dietary fats to reach the liver rapidly and with minimal modification.

The liver is the central organ for yolk lipid deposition. During egg formation, it repackages dietary fatty acids into yolk-targeted lipoproteins, primarily very-low-density lipoproteins for yolk (VLDLy) and vitellogenin and secretes them into the bloodstream. The developing ovarian follicles selectively take up these particles, depositing their lipid into the yolk. Consequently, the fatty acid profile of the egg yolk closely reflects the fatty acid composition of the feed. This highly efficient, source-dependent transfer is the fundamental principle enabling omega-3 enrichment.

The efficacy of this transfer, however, depends on the form of the dietary fatty acid. Hens effectively deposit dietary omega-3s into yolks, but their ability to convert precursors is limited. Dietary ALA from plant sources (e.g., flaxseed) must be converted enzymatically in the liver to longer-chain EPA and DHA, a process that is relatively inefficient in avian species. In contrast, preformed DHA and EPA from marine sources (fish oil) or microalgae are incorporated into yolk lipids more directly and with greater efficiency, leading to higher final concentrations in the egg (Neijat et al., 2016).

Dietary sources and effects on egg composition

Common feed ingredients used for omega enrichment are:

- Flaxseed and ALA-rich ingredients: Feeding flaxseed at 7.5-10% of the diet increases omega-3 content in eggs and improves the omega-6: omega-3 ratio without adverse effects on production and performance (Yalçın & Ünal, 2010). However, higher inclusion can affect sensory characteristics. Flaxseed remains the most cost-effective and widely adopted ingredient for ALA-based enrichment programs

- Fish oil and marine sources: Supplementing diets with fish oil (1-3%) increases EPA and DHA content in yolks more efficiently than plant sources alone (Yalçın & Ünal, 2010).

- Microalgae: Microalgae-derived DHA is a concentrated, sustainable source of preformed long-chain omega-3 fatty acids. Research comparing microalgal oil with fish oil shows similar enrichment outcomes, but egg sensory qualities may be better preserved with microalgal supplementation (Feng et al., 2020).

Effects on layer performance and egg quality

Studies have demonstrated that omega-3 enrichment programs supplying 0.20–0.60% total dietary omega-3 fatty acids do not negatively impact hen performance, egg weight, eggshell quality, or yolk cholesterol when energy and nutrient balance is maintained (Neijat et al., 2016). However, alterations in yolk lipid profiles and sensory attributes, such as flavor, may arise, requiring careful formulation and monitoring. The integration of antioxidants and precise balancing of dietary energy can mitigate oxidative instability associated with high-PUFA diets.

Practical management considerations For consistent production of omega-3 enriched eggs, the following aspects warrant attention:

1. Feed Formulation: Selection of appropriate omega-3 sources considering bioavailability, cost, and target enrichment levels.

2. Oxidative Stability: Omega-3 PUFAs are prone to oxidation; inclusion of antioxidants (e.g., vitamin E) and proper feed storage are essential to preserve nutrient integrity.

3. Market Specifications: Define enrichment targets (e.g., DHA mg/egg) based on buyer requirements.

4. Sensory Quality: Conduct regular sensory evaluation to ensure consumer acceptability, especially with marine-based ingredients.

Omega-enriched egg production represents a scientifically supported strategy to enhance human dietary intake of essential omega-3 fatty acids. Layer diets incorporating flaxseed, fish oil, or microalgal DHA can significantly increase yolk omega-3 content while maintaining productive performance. Adoption of these programs requires balanced nutrition, appropriate ingredient selection, and understanding of market demands.

What are omega fatty acids? Omega fatty acids are polyunsaturated fatty acids (PUFAs) that play essential roles in human health. The most important ones in egg enrichment programs are:

- ALA (α-linolenic acid) – plant-based (flaxseed, canola)

- EPA (eicosapentaenoic acid) – marine origin

- DHA (docosahexaenoic acid) – marine origin, most biologically valuable

Omega-3 fatty acids and human health

Omega-3 PUFAs play critical roles in physiological processes. DHA and EPA, long-chain omega-3s, are associated with cardiovascular health, anti-inflammatory effects, and neural development. A clinical study demonstrated that consumption of omega-3-enriched eggs increased plasma DHA levels significantly compared with regular eggs over 30 days, showing potential to improve systemic omega-3 status in humans (Benny et al., 2025). The enrichment of eggs with omega-3 PUFAs may also improve lipid health indices, such as favorable atherogenic and thrombogenic indexes, suggesting a potential role in chronic disease risk reduction (Radanović et al., 2023).

Fat metabolism and nutritional basis for enrichment in layers

In laying hens, the efficient transfer of dietary fats into the yolk is a direct, hepatic-driven process. Fats from the diet are digested in the small intestine. Bile salts emulsify fats into small droplets, and pancreatic enzymes hydrolyze them into absorbable fatty acids. These are taken up by intestinal cells and packaged into portomicrons—a lipoprotein unique to birds. Due to their less developed lymphatic system compared to mammals, these portomicrons are transported directly to the liver via the portal blood. This direct hepatic portal route allows dietary fats to reach the liver rapidly and with minimal modification.

The liver is the central organ for yolk lipid deposition. During egg formation, it repackages dietary fatty acids into yolk-targeted lipoproteins, primarily very-low-density lipoproteins for yolk (VLDLy) and vitellogenin and secretes them into the bloodstream. The developing ovarian follicles selectively take up these particles, depositing their lipid into the yolk. Consequently, the fatty acid profile of the egg yolk closely reflects the fatty acid composition of the feed. This highly efficient, source-dependent transfer is the fundamental principle enabling omega-3 enrichment.

The efficacy of this transfer, however, depends on the form of the dietary fatty acid. Hens effectively deposit dietary omega-3s into yolks, but their ability to convert precursors is limited. Dietary ALA from plant sources (e.g., flaxseed) must be converted enzymatically in the liver to longer-chain EPA and DHA, a process that is relatively inefficient in avian species. In contrast, preformed DHA and EPA from marine sources (fish oil) or microalgae are incorporated into yolk lipids more directly and with greater efficiency, leading to higher final concentrations in the egg (Neijat et al., 2016).

Dietary sources and effects on egg composition

Common feed ingredients used for omega enrichment are:

- Flaxseed and ALA-rich ingredients: Feeding flaxseed at 7.5-10% of the diet increases omega-3 content in eggs and improves the omega-6: omega-3 ratio without adverse effects on production and performance (Yalçın & Ünal, 2010). However, higher inclusion can affect sensory characteristics. Flaxseed remains the most cost-effective and widely adopted ingredient for ALA-based enrichment programs

- Fish oil and marine sources: Supplementing diets with fish oil (1-3%) increases EPA and DHA content in yolks more efficiently than plant sources alone (Yalçın & Ünal, 2010).

- Microalgae: Microalgae-derived DHA is a concentrated, sustainable source of preformed long-chain omega-3 fatty acids. Research comparing microalgal oil with fish oil shows similar enrichment outcomes, but egg sensory qualities may be better preserved with microalgal supplementation (Feng et al., 2020).

Effects on layer performance and egg quality

Studies have demonstrated that omega-3 enrichment programs supplying 0.20–0.60% total dietary omega-3 fatty acids do not negatively impact hen performance, egg weight, eggshell quality, or yolk cholesterol when energy and nutrient balance is maintained (Neijat et al., 2016). However, alterations in yolk lipid profiles and sensory attributes, such as flavor, may arise, requiring careful formulation and monitoring. The integration of antioxidants and precise balancing of dietary energy can mitigate oxidative instability associated with high-PUFA diets.

Practical management considerations For consistent production of omega-3 enriched eggs, the following aspects warrant attention:

1. Feed Formulation: Selection of appropriate omega-3 sources considering bioavailability, cost, and target enrichment levels.

2. Oxidative Stability: Omega-3 PUFAs are prone to oxidation; inclusion of antioxidants (e.g., vitamin E) and proper feed storage are essential to preserve nutrient integrity.

3. Market Specifications: Define enrichment targets (e.g., DHA mg/egg) based on buyer requirements.

4. Sensory Quality: Conduct regular sensory evaluation to ensure consumer acceptability, especially with marine-based ingredients.

Omega-enriched egg production represents a scientifically supported strategy to enhance human dietary intake of essential omega-3 fatty acids. Layer diets incorporating flaxseed, fish oil, or microalgal DHA can significantly increase yolk omega-3 content while maintaining productive performance. Adoption of these programs requires balanced nutrition, appropriate ingredient selection, and understanding of market demands.

IT’S A MOO POINT

Mouldy Silage

Sam

sama@westernagsupply.com

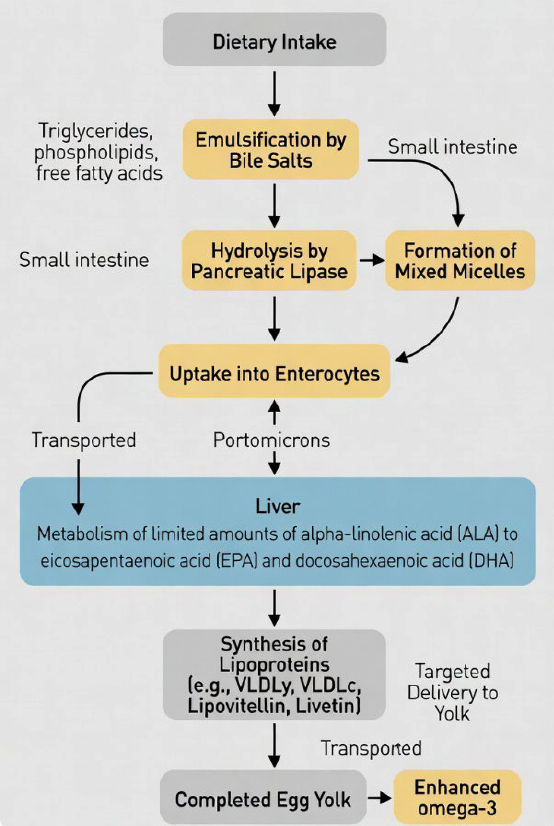

Mouldy silage or fungi grown silage, often caused by poor packing or excessive moisture, insufficient moisture, reduces feed quality and inappropriate harvesting time. Silage quality is an important consideration in feeding cows, and the majority of dairy farms in Canada make silage and feed it throughout the year. Therefore, ensuring mould-free silage is particularly vital for breeding cattle and lactating cows. Mould growth in silage results exerting harmful mycotoxins, potentially causing many problems to cows and production. Spoiled silage should be fed appropriately with a toxin binder to prevent the absorption of mycotoxins from the gut and minimize toxic effects. In order to prevent mould growth in a Total Mixed Ration (TMR) with the affected silage, an appropriate mould-inhibitor should be used. If mould counts are very high, possess apparent discolorations and off-smell, the affected silage should ideally be discarded or heavily diluted (1).

Common moulds in silage are Penicillium, Aspergillus, Fusarium, Monascus, Mucor, Byssochlamys and Alternaria. Most of them would thrive on oxygen and use nutrients in the feed causing reduced nutrient value and eventually producing dangerous mycotoxins that threaten animals’ health. Blue-green mould (Penicillium) is common in storage, while white/red (Fusarium) and yellow/green (Aspergillus) often originate in the field (1,2).

The characteristics of the above moulds are as below.

Penicillium (blue-green) is often seen as blue-green mould. It is a primary storage mould that persists even at low pH levels, after it emerges during the first few days of ensiling. Penicillium moulds found in spoiled silage are highly toxic to cows, primarily producing PR-toxin (bicyclic sesquiterpene mycotoxin), roquefortine C, patulin, and mycophenolic acid. These toxins are responsible for the reduced feed intake, lower milk production, fluctuation of milk components like milk urea nitrogen (MUN), poor reproductive performance (opens, repeats and abortion), kidney damage, and liver damage observed in cows. Over 100,000 CFU/g of silage is generally considered harmful (1).

Aspergillus (yellow-green mould) grows in warm, dry climates and in silage with high oxygen exposure (loose packing), producing harmful toxins like aflatoxin and gliotoxin which significantly reduce feed quality, palatability, and, if consumed, can cause severe health issues, liver damage, reduced milk production, and reproductive failure in breeding cattle. Aspergillus fumigatus often appears as white to dark green mould. Other Aspergillus mould in silage is easily identified by its olive-green to yellow, powdery appearance (1).

Fusarium (red/pink/white) is typically a field mould (ear rot) that enters the silage, producing toxins like deoxynivalenol (vomitoxin), zearalenone, and fumonisin. Field mould means that they proliferate during plant growth and maturation in the field. Their growth is favoured during summer with high humidity (over 70%) and temperatures that fluctuate between those on hot days and cool nights. Ensiling conditions are not favourable for Fusarium species, as they do not tolerate low pH and anaerobic conditions. Nevertheless, some Fusarium toxins are relatively stable or are not completely destroyed during ensiling. Hence, concentrations of Fusarium toxins detected in silage may reflect the contamination levels at the time of harvesting (1).

Monascus (red/orange mould) is frequently found in silage, it appears red or orange, sometimes surrounded by white mycelium. Monascus (M. ruber and M. purpureus) is a xerophilic (dry-loving) or thrives with low moisture and dry conditions in silage, especially when packed too dry and poorly compacted. It acts as a spoilage fungus, producing the nephrotoxic (kidney-damaging) mycotoxin citrinin, which can impair rumen function and lower appetite (feed intake) (1,2).

Mucor/Monilia is common white to gray, fluffy mould associated with spoilage. Mucor mould in silage, appearing as white or gray patches, is a storage fungus that develops due to improper fermentation, longer ensiling process, high moisture, or oxygen exposure, significantly reducing nutritional value and palatability. Even though it may not produce potent mycotoxins, Mucor can cause mycotic abortions and, along with other mould, contributes to rumenitis (inflammation of the rumen) and complex digestive issues (1).

Byssochlamys is a white, powdery mould often found in wet and old silage. When moisture level is higher than 68% at silaging, the chances of this mould occurring is higher. It is a heat-resistant mould coming from soil to the crop silage and it can survive the ensiling process, often causing further spoilage in fermented feeds. These fungi are significant, particularly in 3 to 4 month-old silage, as they can grow in low-oxygen environments and produce harmful mycotoxins, such as patulin and byssochlamic acid. Consumption of contaminated silage can lead to reduced feed intake, lower digestibility, and potential feed-poisoning in cattle (1)

Alternaria is detected in silage in warmer seasons (summer) in field crops and it is considered as a field mould. Alternaria moulds produce compounds such as alternariols, altertoxins, altenuene, tentoxin, phomapyrones, dehydrocurvularin, tenuazonic acid, pyrenochaetic acid and lycopersici toxins. Alternariols have been reported to have DNA strand-breaking activities and are mutagenic and carcinogenic (damage organ development, growth and cause cancer). In addition, they can cause reduced feed intake, gastrointestinal upset, organ damage (liver and kidney), and immune system suppression (poor immunity and prone to other infections) (1).

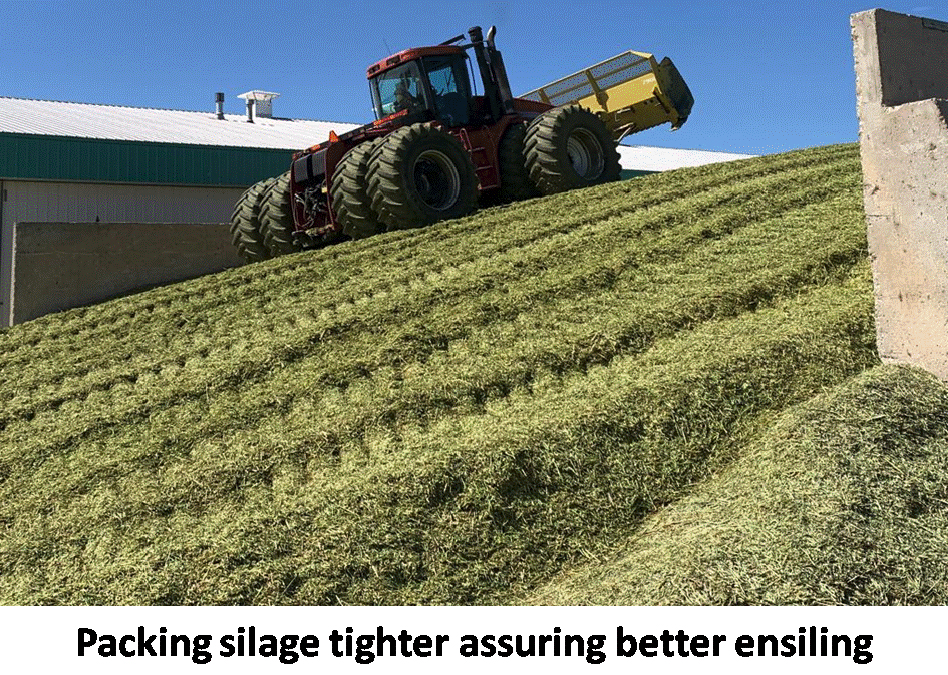

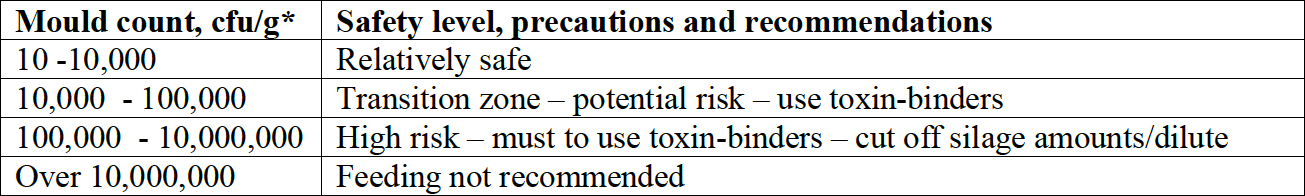

Table 1. Mould counts in silage: Safety levels, precautions and recommendations for ruminants.

cfu/g means colony forming units of mould per a gram of feed. A unit used in microbiology to estimate the number of viable, multiplying fungal cells in a sample, capable of forming a colony on a culture plate, rather than total cells.

cfu/g means colony forming units of mould per a gram of feed. A unit used in microbiology to estimate the number of viable, multiplying fungal cells in a sample, capable of forming a colony on a culture plate, rather than total cells.

Mould and mycotoxins in silage can be minimized by preventing fungal growth before (filed level) and after ensiling (silage). Therefore, good practices such as finding good field crop, timely harvesting, appropriate moisture level, use of a good silage-inoculants, tight packing and proper covering are paramount for successful fast ensiling to accomplish lover pH (4.5 or lower) minimizing mould risks. At the feeding stage, proper silage management (minimum shake and clean face etc), use of mould-inhibitor or microbial rumen-inoculants and use of toxin-binder are essential to reduce mycotoxin contamination of feeds and minimize toxin absorption.

Note: For all articles, references are available upon request.

Common moulds in silage are Penicillium, Aspergillus, Fusarium, Monascus, Mucor, Byssochlamys and Alternaria. Most of them would thrive on oxygen and use nutrients in the feed causing reduced nutrient value and eventually producing dangerous mycotoxins that threaten animals’ health. Blue-green mould (Penicillium) is common in storage, while white/red (Fusarium) and yellow/green (Aspergillus) often originate in the field (1,2).

The characteristics of the above moulds are as below.

Penicillium (blue-green) is often seen as blue-green mould. It is a primary storage mould that persists even at low pH levels, after it emerges during the first few days of ensiling. Penicillium moulds found in spoiled silage are highly toxic to cows, primarily producing PR-toxin (bicyclic sesquiterpene mycotoxin), roquefortine C, patulin, and mycophenolic acid. These toxins are responsible for the reduced feed intake, lower milk production, fluctuation of milk components like milk urea nitrogen (MUN), poor reproductive performance (opens, repeats and abortion), kidney damage, and liver damage observed in cows. Over 100,000 CFU/g of silage is generally considered harmful (1).

Aspergillus (yellow-green mould) grows in warm, dry climates and in silage with high oxygen exposure (loose packing), producing harmful toxins like aflatoxin and gliotoxin which significantly reduce feed quality, palatability, and, if consumed, can cause severe health issues, liver damage, reduced milk production, and reproductive failure in breeding cattle. Aspergillus fumigatus often appears as white to dark green mould. Other Aspergillus mould in silage is easily identified by its olive-green to yellow, powdery appearance (1).

Fusarium (red/pink/white) is typically a field mould (ear rot) that enters the silage, producing toxins like deoxynivalenol (vomitoxin), zearalenone, and fumonisin. Field mould means that they proliferate during plant growth and maturation in the field. Their growth is favoured during summer with high humidity (over 70%) and temperatures that fluctuate between those on hot days and cool nights. Ensiling conditions are not favourable for Fusarium species, as they do not tolerate low pH and anaerobic conditions. Nevertheless, some Fusarium toxins are relatively stable or are not completely destroyed during ensiling. Hence, concentrations of Fusarium toxins detected in silage may reflect the contamination levels at the time of harvesting (1).

Monascus (red/orange mould) is frequently found in silage, it appears red or orange, sometimes surrounded by white mycelium. Monascus (M. ruber and M. purpureus) is a xerophilic (dry-loving) or thrives with low moisture and dry conditions in silage, especially when packed too dry and poorly compacted. It acts as a spoilage fungus, producing the nephrotoxic (kidney-damaging) mycotoxin citrinin, which can impair rumen function and lower appetite (feed intake) (1,2).

Mucor/Monilia is common white to gray, fluffy mould associated with spoilage. Mucor mould in silage, appearing as white or gray patches, is a storage fungus that develops due to improper fermentation, longer ensiling process, high moisture, or oxygen exposure, significantly reducing nutritional value and palatability. Even though it may not produce potent mycotoxins, Mucor can cause mycotic abortions and, along with other mould, contributes to rumenitis (inflammation of the rumen) and complex digestive issues (1).

Byssochlamys is a white, powdery mould often found in wet and old silage. When moisture level is higher than 68% at silaging, the chances of this mould occurring is higher. It is a heat-resistant mould coming from soil to the crop silage and it can survive the ensiling process, often causing further spoilage in fermented feeds. These fungi are significant, particularly in 3 to 4 month-old silage, as they can grow in low-oxygen environments and produce harmful mycotoxins, such as patulin and byssochlamic acid. Consumption of contaminated silage can lead to reduced feed intake, lower digestibility, and potential feed-poisoning in cattle (1)

Table 1. Mould counts in silage: Safety levels, precautions and recommendations for ruminants.

cfu/g means colony forming units of mould per a gram of feed. A unit used in microbiology to estimate the number of viable, multiplying fungal cells in a sample, capable of forming a colony on a culture plate, rather than total cells.

cfu/g means colony forming units of mould per a gram of feed. A unit used in microbiology to estimate the number of viable, multiplying fungal cells in a sample, capable of forming a colony on a culture plate, rather than total cells.

Mould and mycotoxins in silage can be minimized by preventing fungal growth before (filed level) and after ensiling (silage). Therefore, good practices such as finding good field crop, timely harvesting, appropriate moisture level, use of a good silage-inoculants, tight packing and proper covering are paramount for successful fast ensiling to accomplish lover pH (4.5 or lower) minimizing mould risks. At the feeding stage, proper silage management (minimum shake and clean face etc), use of mould-inhibitor or microbial rumen-inoculants and use of toxin-binder are essential to reduce mycotoxin contamination of feeds and minimize toxin absorption.

Note: For all articles, references are available upon request.

ANNOUNCEMENTS

When you work with WAGS, you WIN!

Congratulations to the WAGS partners who made it to the H@ms Marketing December Top 10 list for carcass quality of pigs going to either Thunder Creek, Britco, North 49, or Olymel.

Well done guys!

THUNDER CREEK, BRITCO and NORTH 49

INDEXING

8TH Vanguard Farming Co. Ltd.

PERCENT DEMERIT FREE

9TH Vanguard Farming Company Ltd.

LEAN PERCENTAGE & LOIN DEPTH

Lean Percent Target

1st Vanguard Farming Co. Ltd.

2nd Raley colony Ltd.

8th New Dale Hutterian Brethren

Loin Depth Target

7th Wymark Farming Company Ltd.

10th Raley Colony Ltd.

CORE AREA AND SORT

% in Core Area

1st Shamrock Farming Co. Ltd.

6th Wymark Farming Company Ltd.

9th Bench Farming Company

Carcass Wt. Target

6th Raley Colony Ltd.

7th Hillridge Farming Co.

10th Garden Plane Farming Company

OLYMEL

INDEXING

1st Summerland Colony Farming

3rd Old Elm Farming Co. Ltd.

8th Clearlake Farming

PERCENT DEMERIT FREE

5th Sovereign Farming Company

LEAN PERCENT TARGET

3rd Clear Lake Farming

LOIN DEPTH TARGET

8th Summerland Colony Farming

PERCENT IN CORE AREA

4th Summerland Colony Farming

10th Clearlake Farming

Carcass Wt. Target

2nd Old Elm Farming Co. Ltd.

5th Summerland Colony Farming

Well done guys!

THUNDER CREEK, BRITCO and NORTH 49

INDEXING

8TH Vanguard Farming Co. Ltd.

PERCENT DEMERIT FREE

9TH Vanguard Farming Company Ltd.

LEAN PERCENTAGE & LOIN DEPTH

Lean Percent Target

1st Vanguard Farming Co. Ltd.

2nd Raley colony Ltd.

8th New Dale Hutterian Brethren

Loin Depth Target

7th Wymark Farming Company Ltd.

10th Raley Colony Ltd.

CORE AREA AND SORT

% in Core Area

1st Shamrock Farming Co. Ltd.

6th Wymark Farming Company Ltd.

9th Bench Farming Company

Carcass Wt. Target

6th Raley Colony Ltd.

7th Hillridge Farming Co.

10th Garden Plane Farming Company

OLYMEL

INDEXING

1st Summerland Colony Farming

3rd Old Elm Farming Co. Ltd.

8th Clearlake Farming

PERCENT DEMERIT FREE

5th Sovereign Farming Company

LEAN PERCENT TARGET

3rd Clear Lake Farming

LOIN DEPTH TARGET

8th Summerland Colony Farming

PERCENT IN CORE AREA

4th Summerland Colony Farming

10th Clearlake Farming

Carcass Wt. Target

2nd Old Elm Farming Co. Ltd.

5th Summerland Colony Farming

THE WAGS TEAM

David Borsboom – Sales Manager

Harry Korthuis – Sales Manager

Adam Krieser – Sales Manager

Richard Kshyk – Sales Manager

Doug Richards – Sales Manager

Tony Rock – Sales Manager

Gordon Van Dasselaar –Sales Manager

C Ann Cornell – Office Coordinator, Great Falls, Montana

Anne Dyck - Office Assistant, Lethbridge, Alberta

Hailey Moors – Office Manager, Lethbridge, Alberta

Harry Korthuis – Sales Manager

Adam Krieser – Sales Manager

Richard Kshyk – Sales Manager

Doug Richards – Sales Manager

Tony Rock – Sales Manager

Gordon Van Dasselaar –Sales Manager

C Ann Cornell – Office Coordinator, Great Falls, Montana

Anne Dyck - Office Assistant, Lethbridge, Alberta

Hailey Moors – Office Manager, Lethbridge, Alberta

Darlene Thorburn – Office Coordinator, Swift Current, Saskatchewan

Bryce Rollet – Logistics Coordinator, Lethbridge, Alberta

Saman Abeysekara – Ruminant Nutritionist

Ruben Garzon – Poultry Nutritionist

Santosh Lamichhane – Poultry Nutritionist

Joaquin Sanchez – Swine Nutritionist

Danilo Sotto – Director of Nutrition

Darcy MacDonald – Director of Business Development

Tom Dowler – General Manager

Bryce Rollet – Logistics Coordinator, Lethbridge, Alberta

Saman Abeysekara – Ruminant Nutritionist

Ruben Garzon – Poultry Nutritionist

Santosh Lamichhane – Poultry Nutritionist

Joaquin Sanchez – Swine Nutritionist

Danilo Sotto – Director of Nutrition

Darcy MacDonald – Director of Business Development

Tom Dowler – General Manager